|

|

| PARS Engineering, spol. s r. o.

|

30+

|

years of experience |

| in engineering |

We're a stable company in the field of

engineering and automation since 1993.

We

have a wide portfolio of experience in design, manufacturing, assembly

and implementation of investment deliveries in agreed terms and quality.

Manufacturing

facilities with an area of

2000 m2 are situated

in the town of Rychvald

in the district of Karviná.

Production

background allows us to manufacture, assemble and test the completed

lines.

|

|

Company portfolio

|

|

1. Profile

punching

- we perform non-deforming punching of

hollow profiles, open sections and

shaped rods

- used for gondola retail shelving, steel and aluminium supporting and

cover

structures

|

|

2. Punching machines

- we manufacture punching machines of the

SIRIUS Plus standard production

series for punching profiles

- punching standard profiles by their croos-section

- rods/hollow profiles + pipes + flat ovals,

open sections L, U, C

- IPE and HEB bars

- used for stems and bracket arms of gondola shelves or for bridge

girder systems

|

|

3. Assembly

lines

- devices for repeated assembly of

individual parts into assemblies

- automation of assembly with measuring and adjusting parameters of the

product

- repeatability and short assembly cycles - circa 6 s/assembly

- quality and parameters diagnostics and sorting out incidental rejects

from

production line

- used e.g. for IKEA furniture frames, electromechanical elements and

photovoltaic

systems

|

|

4.

Production lines

- connecting our punching machines into

automated production

- development of

new production lines with new punching technology

for complexly shaped sections/profiles

- followed up by our assembly lines

- punching holes into profiles in large-lot productions |

|

5. Fixtures

- devices for assembling parts even for

complex product assemblies

- clipping control panels for cars

- SIRIUS Plus fixtures for manually operated punching - for press or

with

separate drive

|

|

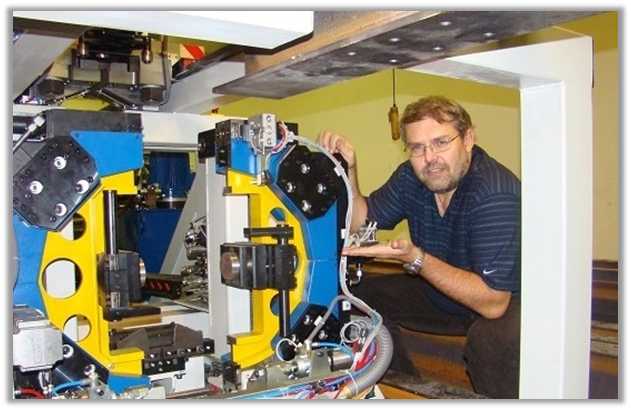

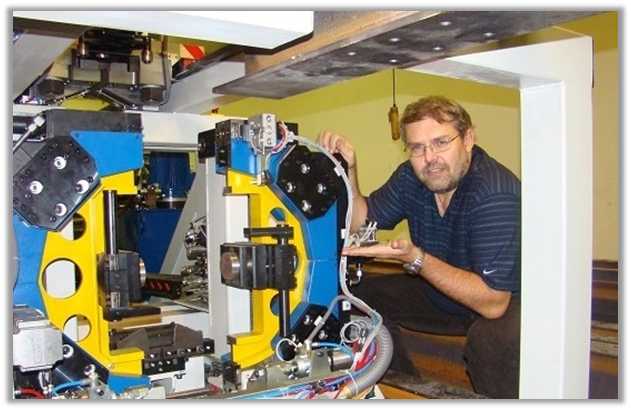

6. Production background

|

|