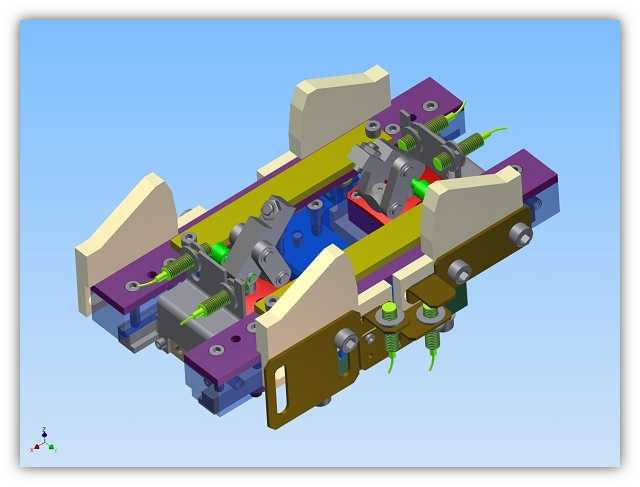

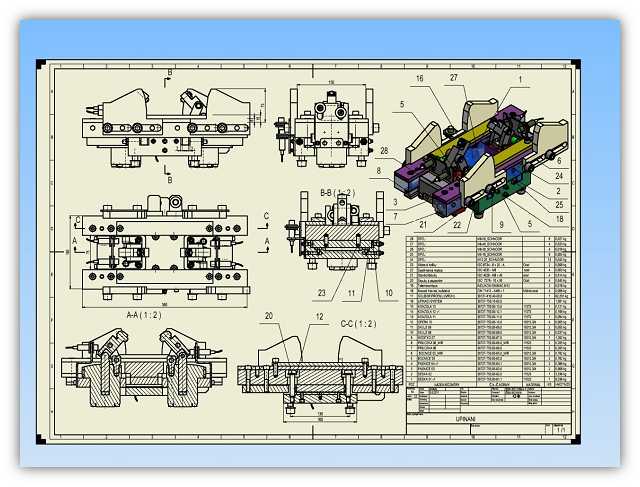

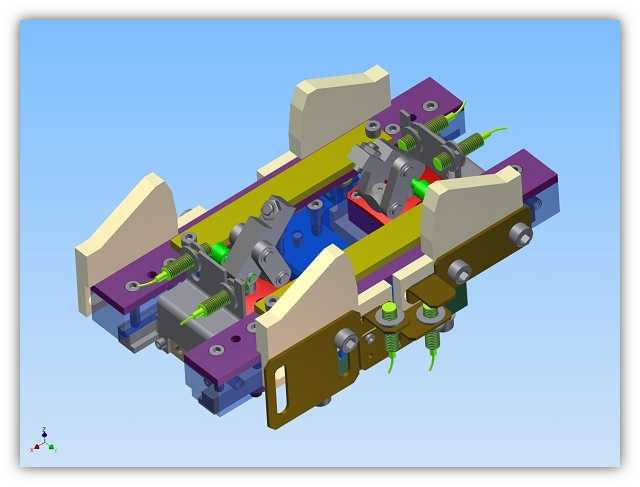

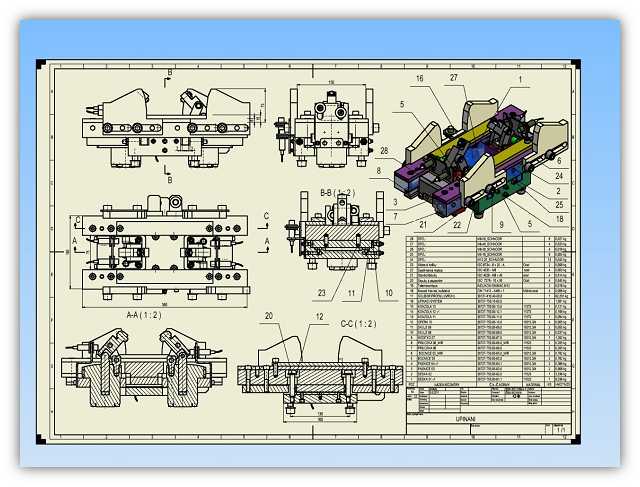

1. CAD: 3D model + 2D

drawings

|

|

|

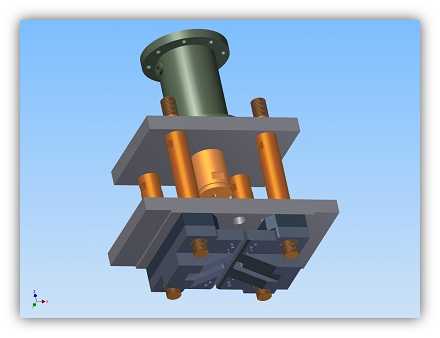

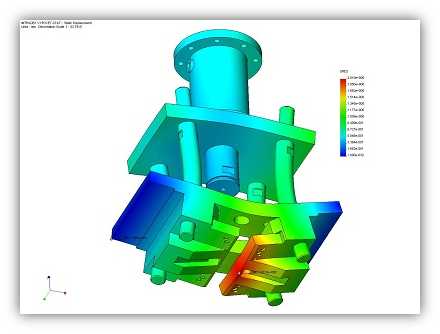

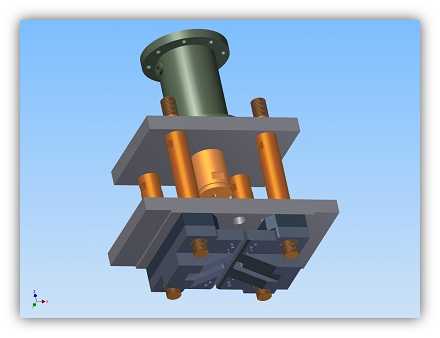

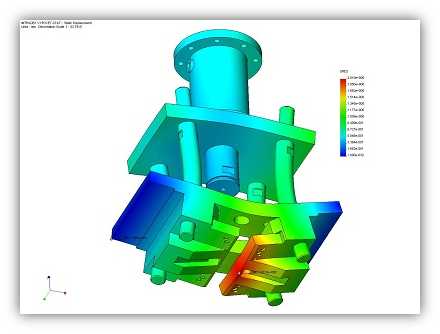

2. CAE: simulation of load behavior

|

|

|

|

3. CAM: we carry out production on modern CNC machine tools

|

|

C

400 HERMLE

- machinig center for 5-axis machining

- control system Heidenhain TNC 640

- max. rotation speed:18000 ot/min

-

linear shift X/Y/Z 35 m/min

- platen 1070x700 mm

- travel line 850x700x500 mm

- weight load of the table 2000 kg

|

|

|

DMG

MORI NLX 2500/700

-

turning center for 6-axis machining

- control system CELOS

- tool rotation 10000 ot/min

- workpiece d = 80 mm, l = 200/705 mm

- workpiece weight max. 250 kg

|

|

FANUC Robocut -

C600iA

- electroerosion wire EDM FANUC

- high quality cut surface Ra 0,15

μm

- workpiece weight 1000 kg

- machined size 600x400, Z-axis 310 mm

- max. taper angle 30°/150

mm

- min. programme step 0,0001 mm

- wire diameter 0,1-0,3 mm

|

|

Engraving LASER HXP

20E

- marking produced parts 110x110 mm

- rotary axis for marking on cylindrical surface

- LASER power 20 W

- min. line width 0,02 mm

- min. character size 0,2 mm

|

|

4. Heat treatment and coating

|

Vacuum hardening

We use vacuum hardening when hardness and toughness of shear tools are

required.

Vacuum heating is followed by cooling with nitrogen gas, so there are

no dimensional changes and the surface is not scaled.

|

Nitrocarburizing

Nitrocarburizing

is a surface treatment, a thermochemical diffusion process meant to

provide an anti-wear resistance on the surface layer, to improve

fatigue resistance by up to 120 % and to improve corrodion resistance.

It

is carried out at temperatures up to 600 °C, which minimizes

deformations and creates a tough core with a hard case layer up to a

thickness of 50 μm.

|

Blackening and zinc coating

All

steel working parts are surface treated by alkaline blackening - an

oxide layer forms on the surface, combined with oiling creates a proven

surface protection.

Additionally there's an option of galvanizing and blue passivation.

|

Powder coating (komaxit - RAL colour

standard)

External

covers and visible parts are treated by electrostatic application of

powder paint. WHen heated to 180 °C, hardening occurs and a

high-quality surface layer is formed.

|

5. Welded frames manufacturing

|

For

the purpose of manufacturing supporting frames and testing of the

assembled production lines we have 2 big manufacturing halls at our

disposal, including a fully equipped locksmith workshop.

|

|

|

6. Completion + assembly

|

Main assembly

of machines and lines up to 10x10 m is carried out in a separate

manufacturing hall.

|

|

|

7. Despatch

|

Machines and lines are

despatched onto the loading area of trucks in the indoor environment of

the manufacturing hall.

|

|

|